Pyrolysis plants in Europe are emerging as a beacon of sustainable innovation, particularly in the realm of plastic and tire conversion. With increasing concerns about plastic pollution and tire waste management, these facilities offer a viable solution by converting discarded plastics and tires into valuable products such as fuel oil, carbon black, and syngas. This article examines the operation, benefits, challenges, and future prospects of pyrolysis plant in Europe, focusing on their role in mitigating environmental impacts and fostering a circular economy.

Understanding Pyrolysis Plants for Plastic and Tire Conversion

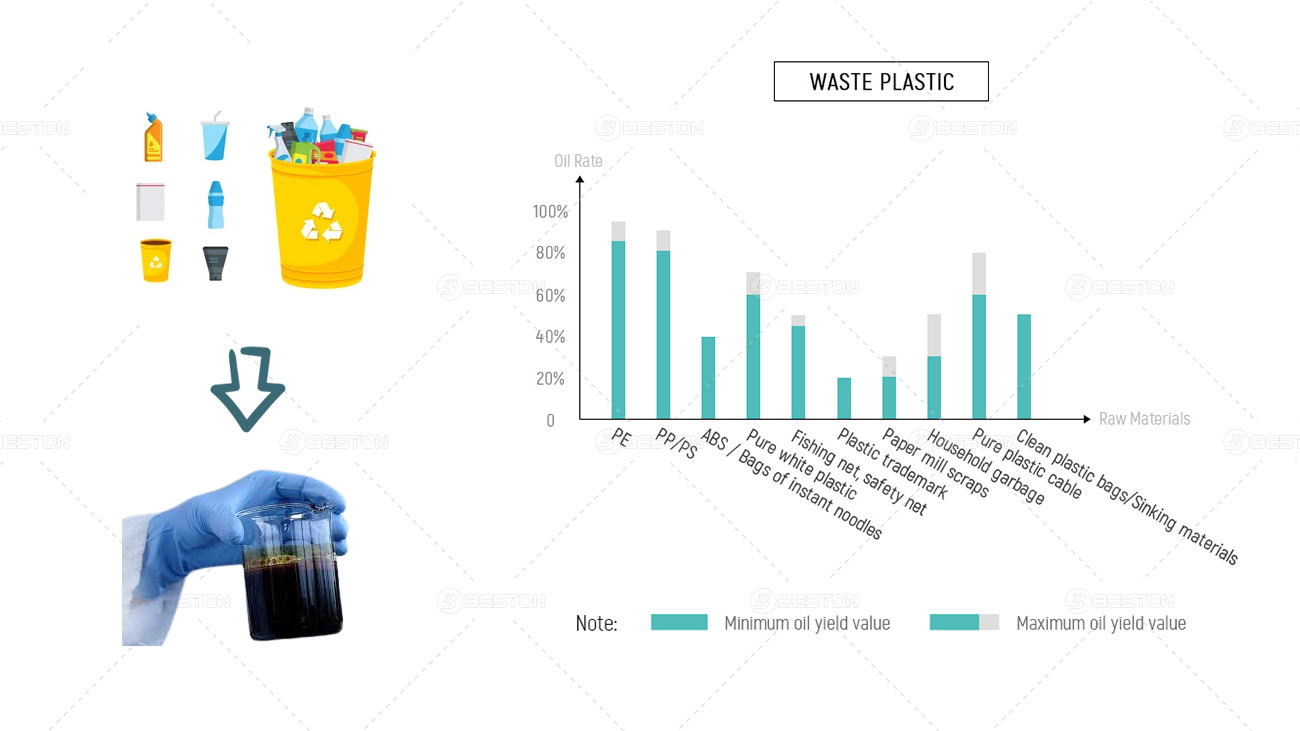

Pyrolysis plants designed for plastic and tire conversion utilize the pyrolysis process to thermally decompose these materials into useful products. Pyrolysis involves heating plastics or tires in the absence of oxygen, leading to the breakdown of complex hydrocarbons into simpler molecules. The resulting products can be refined into fuels, chemicals, and other valuable commodities.

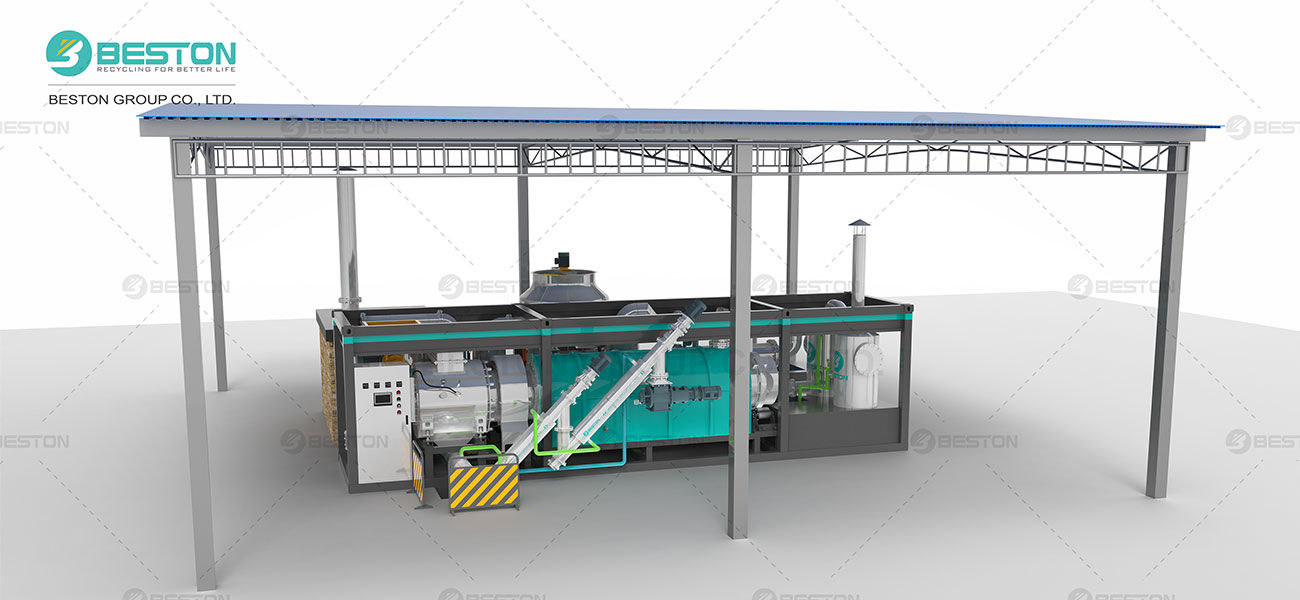

Key Components of Pyrolysis Plants for Plastic and Tire Conversion:

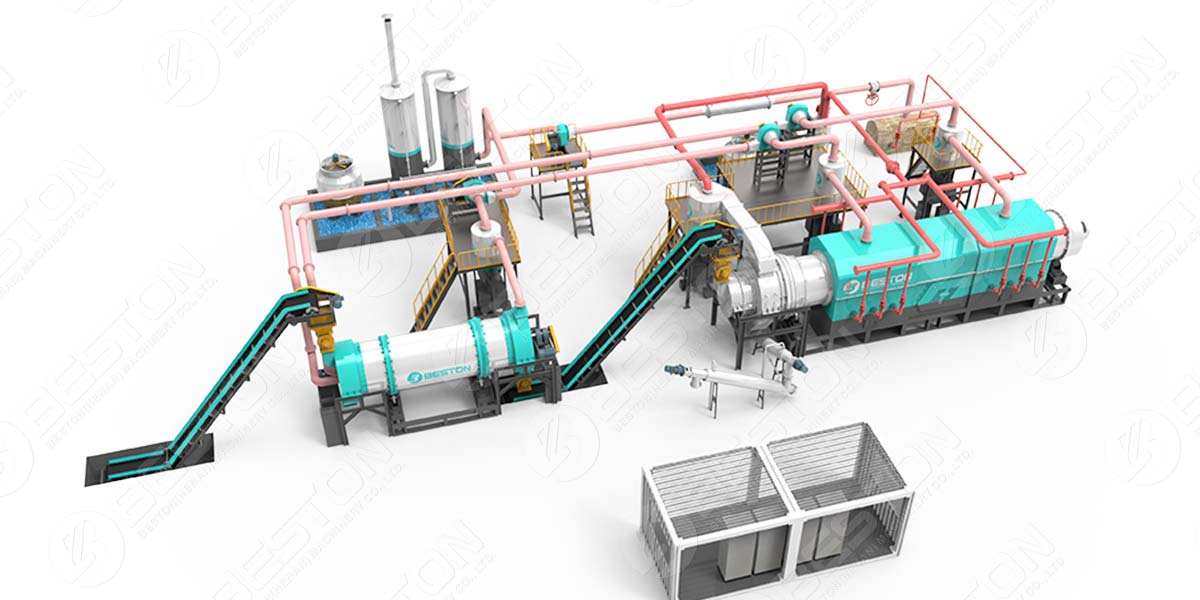

Feedstock Preparation: Plastic waste and scrap tires undergo preprocessing to remove contaminants, such as metals and non-recyclable materials, and reduce particle size for efficient pyrolysis.

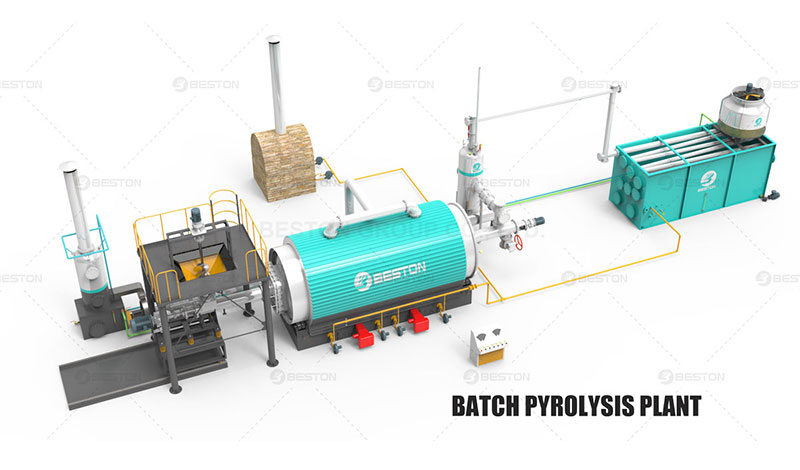

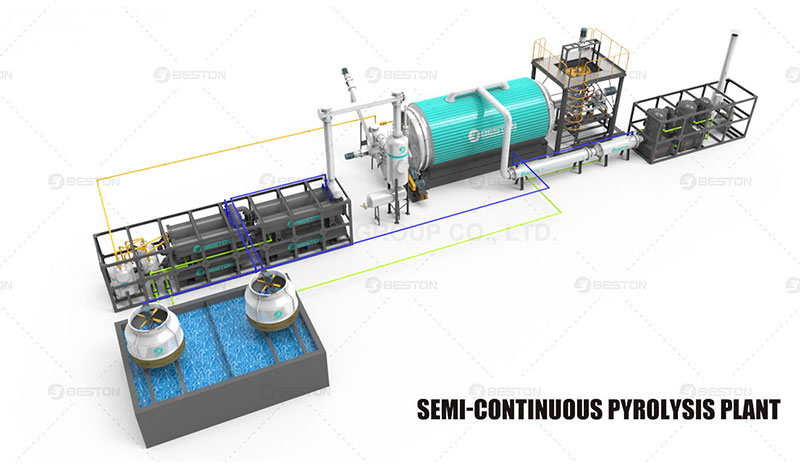

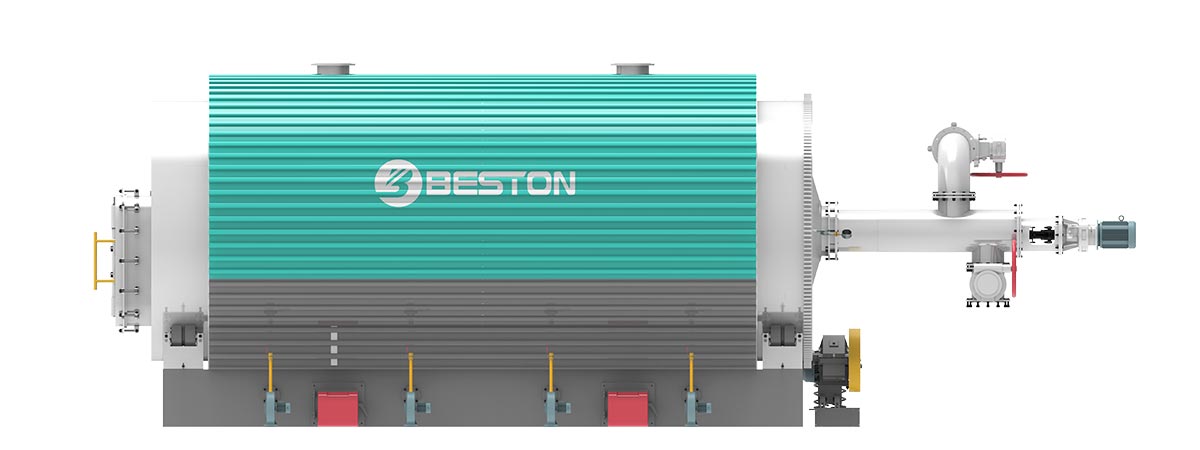

Pyrolysis Reactor: The pyrolysis reactor is the core component where plastic or tire feedstock is subjected to high temperatures in an oxygen-deprived environment. Reactor designs may vary depending on the type of feedstock and desired products, including rotary kilns, fluidized bed reactors, and fully continuous pyrolysis plant.

Heating and Cooling Systems: Pyrolysis plants are equipped with heating systems to raise the temperature within the reactor and initiate the pyrolysis process. Cooling systems facilitate the condensation and collection of pyrolysis products, ensuring efficient recovery and separation.

Product Recovery and Refining: The products of pyrolysis, including fuel oil, carbon black, and syngas, are recovered and subjected to further refining processes to improve quality and purity. Fractional distillation, filtration, and purification techniques are commonly employed to refine pyrolysis products for commercial use.

Benefits of Pyrolysis Plants for Plastic and Tire Conversion

Waste Diversion and Recycling: Pyrolysis plants offer an environmentally sustainable solution for diverting plastic and tire waste from landfills and incineration facilities. By converting these materials into valuable products, such as fuel oil and carbon black, pyrolysis plants contribute to the circular economy by closing the loop on resource utilization and waste generation.

Resource Recovery: Plastic and tire pyrolysis enables the recovery of valuable resources embedded in these materials, including hydrocarbons, carbon black, and steel. These recovered resources can be used as feedstock for various industries, reducing the need for virgin materials and minimizing environmental impacts associated with resource extraction.

Energy Production: Pyrolysis plants generate fuel oil and syngas as primary products, which can be used as clean fuels for heat and power generation. Fuel oil derived from plastic and tire pyrolysis can substitute for conventional fossil fuels in industrial boilers, furnaces, and diesel engines, reducing greenhouse gas emissions and dependency on non-renewable resources.

Carbon Sequestration: The carbon black produced during plastic and tire pyrolysis can be utilized as a sustainable alternative to virgin carbon black in various applications, including rubber manufacturing, plastics production, and construction materials. By replacing virgin carbon black with recycled carbon black, pyrolysis plants contribute to carbon sequestration and resource conservation.

Challenges and Considerations

Feedstock Quality and Contamination: Ensuring the availability of high-quality feedstock free from contaminants is essential for the efficient operation of pyrolysis plants. Contaminants such as metals, glass, and non-combustible materials can degrade pyrolysis reactor performance and reduce the quality of the resulting products. It also affects the pyrolysis plant price.

Regulatory Compliance: Compliance with regulatory requirements governing waste management, air emissions, and product quality standards is a significant challenge for pyrolysis plant operators. Meeting stringent regulatory standards and obtaining permits for waste handling and emissions control can add complexity and cost to project development and operation.

Economic Viability: The economic viability of pyrolysis plants depends on factors such as capital investment, operational costs, product prices, and market demand. Fluctuations in oil prices, competition from traditional fossil fuels, and uncertainty surrounding regulatory frameworks can impact the profitability of pyrolysis projects and deter investment.

Technology Optimization: Optimizing pyrolysis technology for plastic and tire conversion requires continuous innovation and research to improve process efficiency, product quality, and environmental performance. Developing robust reactor designs, efficient heating and cooling systems, and effective product recovery methods is essential for maximizing the economic and environmental benefits of pyrolysis plants.

Future Prospects and Opportunities

Advanced Technologies: Continued research and development in pyrolysis technology hold promise for advancing the efficiency, scalability, and versatility of plastic and tire conversion processes. Innovations such as microwave pyrolysis, catalytic pyrolysis, and integrated process configurations can enhance product yields, reduce energy consumption, and expand the range of feedstocks suitable for pyrolysis.

Market Development: Developing markets for pyrolysis products, including fuel oil, carbon black, and syngas, is critical for the long-term viability of pyrolysis plants. Building partnerships with end-users in industries such as energy, manufacturing, and transportation can create opportunities for product off-take agreements and revenue generation.

Policy Support: Policy frameworks that incentivize waste valorization, renewable energy production, and circular economy initiatives can accelerate the deployment of pyrolysis plants for plastic and tire conversion. Measures such as extended producer responsibility schemes, carbon pricing mechanisms, and renewable energy subsidies can create a favorable regulatory environment for pyrolysis projects.

Industry Collaboration: Collaboration among stakeholders, including government agencies, industry associations, research institutions, and technology providers, is essential for driving innovation and overcoming common challenges in the pyrolysis sector. Knowledge sharing, technology transfer, and capacity building initiatives can facilitate the adoption of best practices and foster the growth of the pyrolysis industry.

Conclusion

Pyrolysis plants in Europe represent a sustainable solution for converting plastic and tire waste into valuable products, including fuel oil, carbon black, and syngas. By harnessing the potential of pyrolysis technology, Europe can address environmental challenges associated with plastic pollution and tire waste management while creating economic opportunities and promoting resource efficiency. With continued investment, innovation, and policy support, pyrolysis plants will play an increasingly important role in Europe’s transition towards a circular economy and a greener, more sustainable future. Find more information from https://www.bestongroup.com/ru/.