Disposing plastic in a safe and environment-friendly manner has been a global issue for a long time. With more than 300 million plastic products being developed each year, it has become hugely essential to resolve this issue once and for all. The pyrolysis plant has, therefore, taken the world of technology by storm. The perfect pyrolysis plant design ensures that each and every speck of plastic and rubber is effectively converted into industrial fuel. With this state-of-the-art machinery dominating the market, the problems related to disposing of plastic can be minimized to great effect.

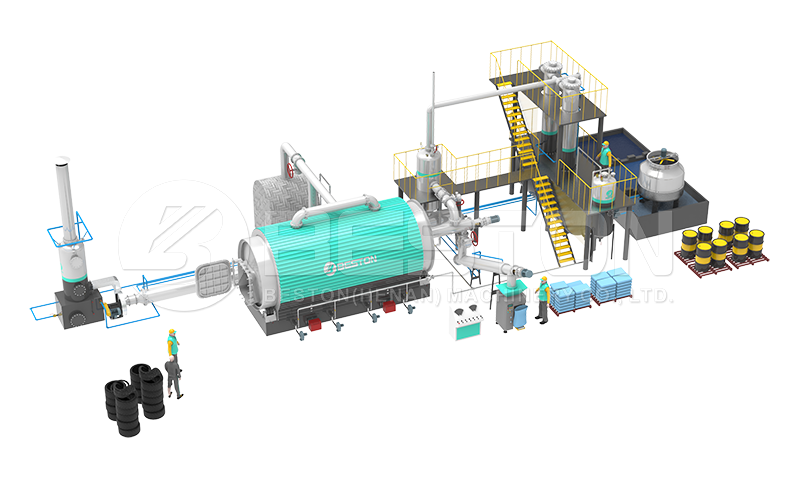

Pyrolysis plants are essentially run using a continuous liquefaction technology which, with the help of a catalytic breakdown process, produces end products in the form of liquids and gases. These products are then used as industrial fuels to produce energy. The exceptional properties of this machinery make it a vastly useful device. In addition to its capability of processing a massive amount of waste material in a short time, the plant also features ground-breaking innovations that reform the reactor’s surfaces. The distinguishing catalyst and condenser in parallel with a highly efficient reactor are capable of providing an output that is not harmful to the environment.

Opting for the perfect design of plastic pyrolysis machine is proving to be extremely beneficial. One of its prime features is that it can effectively convert a gigantic amount of waste material into useful products in a surprisingly short amount of time. An auto feeder transports the waste material to the reactor where heat is used to convert the plastic into pyrolysis oil, waste gas, and carbon black. The plant ensures that the heat is later reused in the process instead of letting it escape into the environment. Apart from converting 95% of the waste material into useful products, the process is also environmentally friendly. The perfect design of plastic to fuel conversion plant promises safety and efficiency and allows you to use both tires and plastic as the raw material. Also, the machine is extremely easy to operate. You will not need to hire any expert labor to run the equipment efficiently. Finally, the use of an innovative catalyst helps reduce coke yield and enhances the output of the process significantly.