Are you planning to buy a biomass pyrolysis plant? Do you want to get the best value for your money when buying this plant? Are you aware of the major brands in this space? In this blog post, we will explore all these questions and help you make the right choice when buying a pyrolysis plant.

Choose the Right Configuration for the Plant

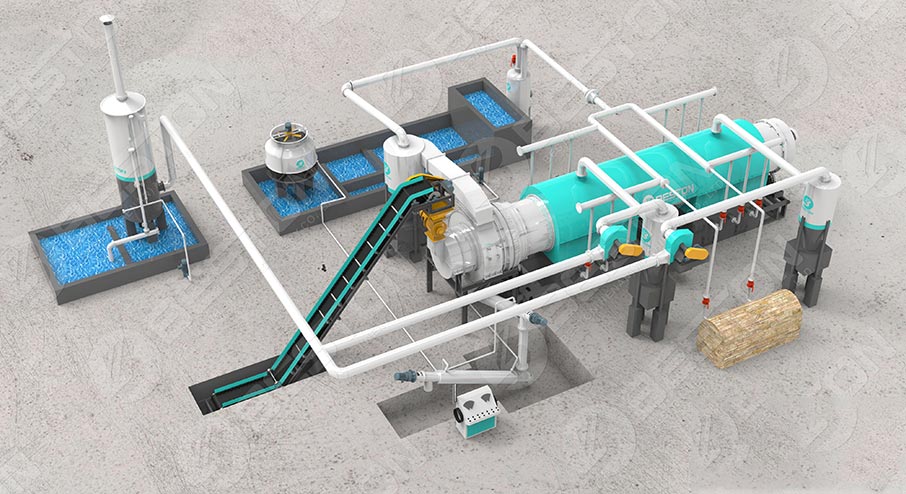

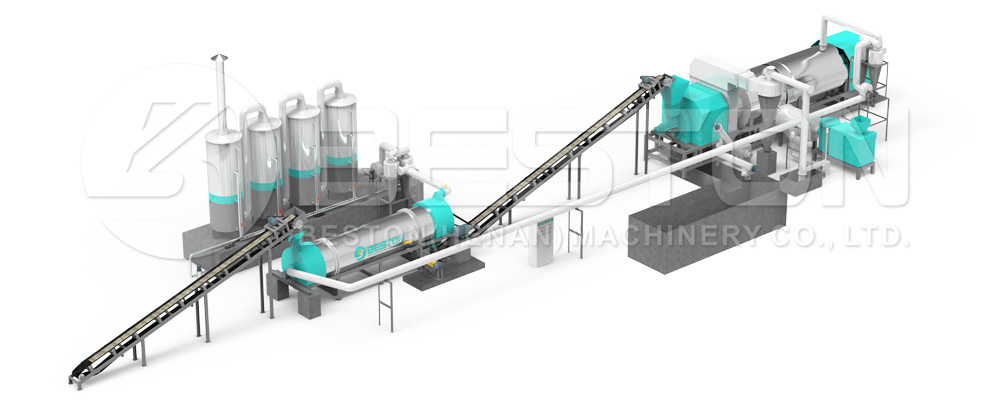

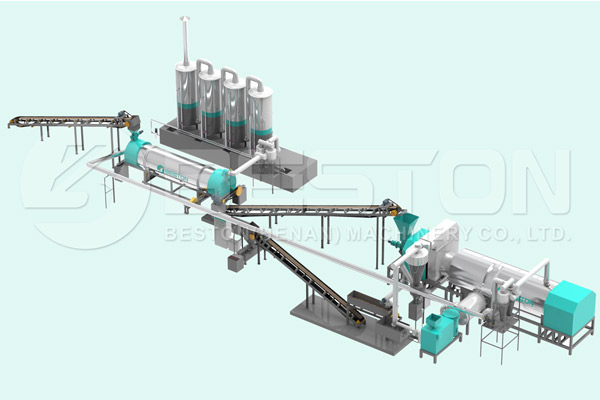

One of the first things you need to decide on is the configuration of the plant. You can buy this biomass pyrolysis plant in both stationary and portable configurations. Both these types have their own advantages and limitations. The biggest advantage of a mobile pyrolysis plant is that you can drive it right to the location.

Sometimes, it is not financially feasible to bring all the raw material that needs to be processed to a central location. The cost isn’t worth it. In such cases, driving a pyrolysis plant right to the location of the raw material is much more financially feasible.

On the other hand, a stationary plant also offers several advantages. The biggest advantage is that you can have as much capacity as you want which is not possible with a mobile unit. A mobile unit is always going to have limited processing capacity.

Choose the Right Manufacturer

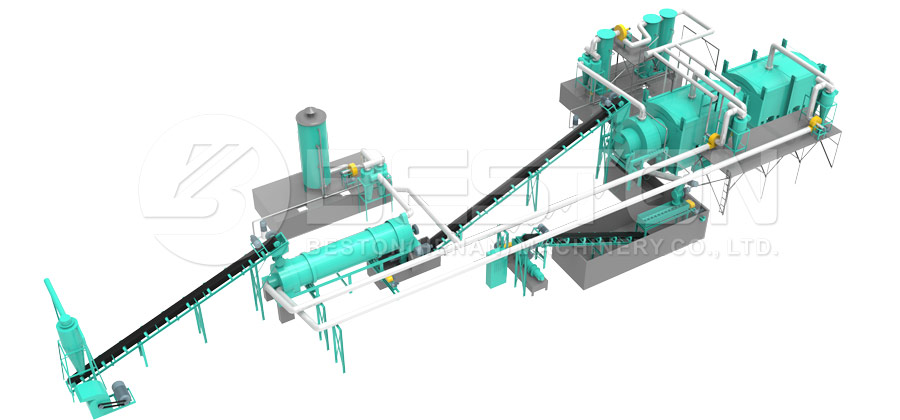

There are almost an endless number of manufacturers of these plants. Since the demand for these plants has increased substantially over the last decade, a number of businesses have also jumped into manufacturing of coconut shell charcoal making machine. Unfortunately, not every manufacturer out there has the required level of design and manufacturing expertise and that shows in the product quality.

They often use low-grade materials for making various components. Their designs are inefficient when compared to designs by reputed manufacturers. Also, they lag behind in terms of after sales service. It is recommended to choose a reputed manufacturer that has been active in this industry for several years and is known for product quality and after sales service. Make sure the design is perfect and already operational in various parts of the world.

Price Comparison

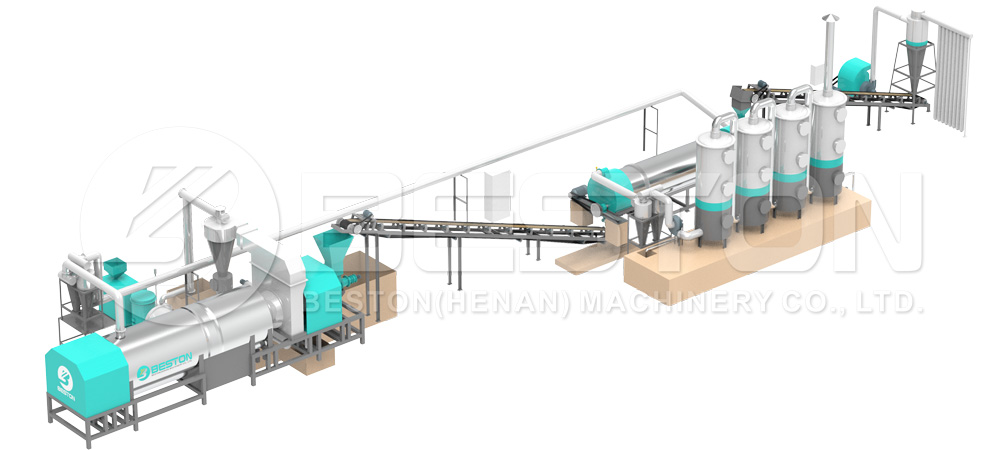

Every smart buyer knows that shopping around is the best way to buy something at the minimum possible price. In order to buy this wood charcoal making machine at the lowest price, you should first decide on the specifications and after finalizing your specifications, ask for estimates from 3 to 5 different manufacturers. Do not limit your search to only domestic suppliers.

Identify some foreign manufacturers or suppliers and ask them to provide a detailed estimate. It will help you in negotiations and allow you to get the best value for your money. Before making a final choice, you need to carefully go through the detailed estimate, especially the warranty terms and conditions.

Reputed companies stand behind their product and that confidence reflects in their warranty. They provide a generous warranty for various components. This is why you should choose a company with excellent warranty terms. It will help you in getting the best value for your money in the long run.

Final Thought

Overall, there are several companies selling biomass pyrolysis plants. It wouldn’t be wise to buy one without proper research. You should focus on choosing the right configuration and the right manufacturer. Do not worry too much about price. Quality is always sold at a premium. Don’t be afraid to spend a little extra to buy better quality and more reliable plant. Get competitive charcoal making machine price here.