Pyrolysis equipment works on the principle of a chemical reaction that features the molecular breakdown of large-sized molecules into smaller molecules at elevated temperatures and in the absence of oxygen. The process involves the simultaneous change of both physical shape and chemical composition of the molecules, which is irreversible.

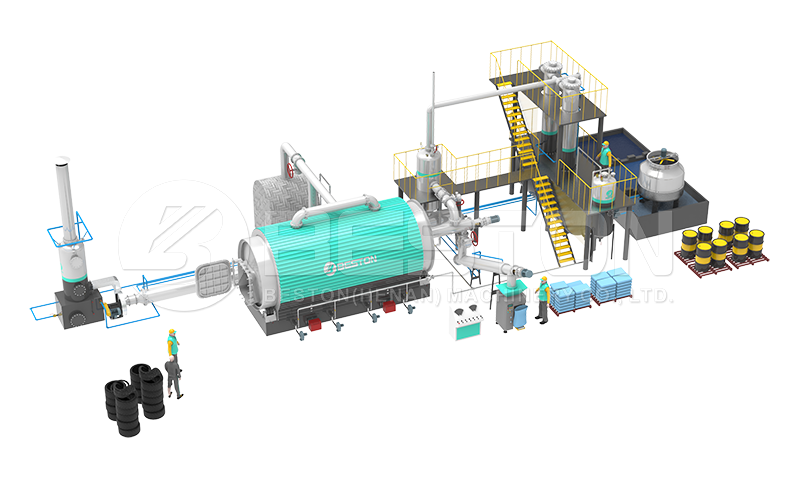

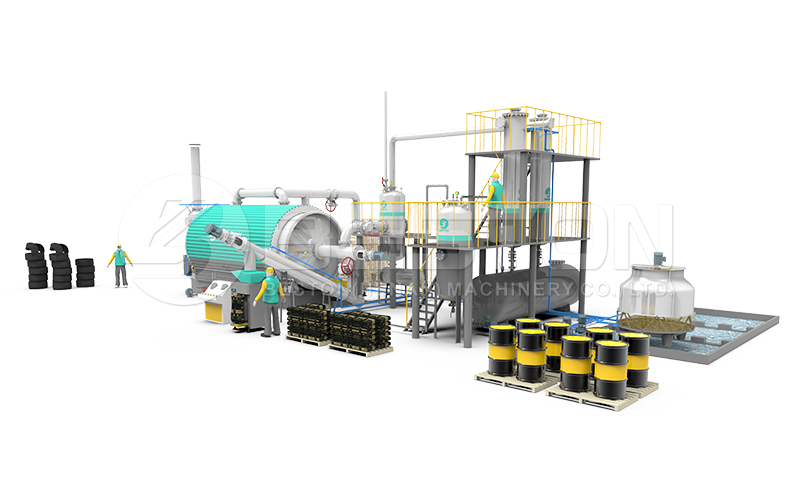

The “waste tire pyrolysis plants” also work on the aforementioned principle. These plants can effectively convert waste tire into fuels, such as oil, carbon black, and hydrocarbon gas, etc. Here, the raw material is either waste tire or waste plastic. Then, the raw materials are heated in the reactor in order to generate fuels, oil, and gas.

Benefits of Using Waste Tyre Pyrolysis Plant:

This is renewable & environmental equipment that efficiently deals with the waste. Across the entire world, millions of car tires are discarded annually. Pyrolysis of such scrap or waste tire can be an incredibly attractive alternative instead of the disposal in vacant landfills. Plus, the system also allows the high energy content of the waste tire to be recovered as useful fuels. Hence, the benefits of using waste tyre pyrolysis plant are actually many. Here’s a summarized list of key benefits of using waste tyre pyrolysis plant.

1. Using a waste tyre recycling pyrolysis plant, you can definitely get an excellent, eco-friendly & cost-effective solution for waste tyres recycling.

2. On an average, the entire pyrolysis process can result in a yield of around 38-56% oil, 14-56% charcoal, and 10-30% gas. The oil produced is mainly composed of diesel, kerosene, benzene, fuel oil & heavy fuel oil. Hence, the produced oil can be further refined and used for operating any vehicle.

3. The environment pollution has really become the most serious issue nowadays. Obviously, waste tire pyrolysis plants provide a meaningful solution to it while promoting an eco-friendly solution by eliminating the hazards of land pollution caused by the waste tire.

4. By converting the waste into energy, the pyrolysis equipment offers a renewable energy source too.

The application of Waste Tyre Pyrolysis Plant falls under the following categories of industrial projects :

2. Renewable energy project;

3. Waste tire and plastic control equipment;

4. Petrochemical;

5. Sustainable pollution control equipment;

Why Buy “Waste Tyre Pyrolysis Plant for Sale” – Key Points to Consider :

As you’ve now revealed the major benefits and applications of waste tyre pyrolysis plant, you must be planning to buy incredibly useful equipment. As a professional waste tyre pyrolysis plant manufacturer, Beston has developed the plant with many features. In this context, this particular section will help you to make a meaningful decision about your purchase.

1. The waste tyre pyrolysis plants, fabricated using the world-class design & technology can provide higher fuel output while incurring a lower cost.

2. The advanced plant features the fully continuous tyre pyrolysis plant, semi-continuous and batch processing in order to stimulate its overall efficiency.

3. Also, the entire process is environment-friendly which promotes the use of green technology.

4. More than 90% of the machinery parts of any waste tyre pyrolysis equipment are non-moving which reduces the chances of recurring maintenance.

5. This advanced pyrolysis equipment is also self-sufficient which doesn’t actually require any external fuel for heating.

6. These systems also use cutting-edge technologies in order to improve profitability, safety, and ease of operation.

Final Words

With this aforementioned information, it’s pretty clear that you can definitely use waste tyre pyrolysis plant in order to obtain a meaningful and profitable solution for the effective recycling of waste.