As we traverse the diverse terrain of pyrolysis plants, each type unveils its distinctive strengths and applications. The batch pyrolysis plant excels in precision, catering to specialized needs, while the semi-continuous pyrolysis plant strikes a balance for those seeking a middle ground. Finally, the continuous pyrolysis plant stands tall as the epitome of efficiency, tailored for industrial giants with an insatiable appetite for waste conversion.

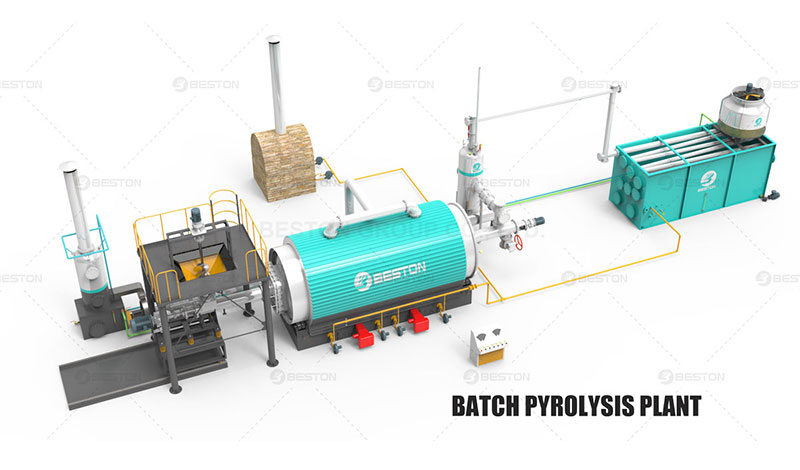

Batch Pyrolysis Plant: The Art of Precision

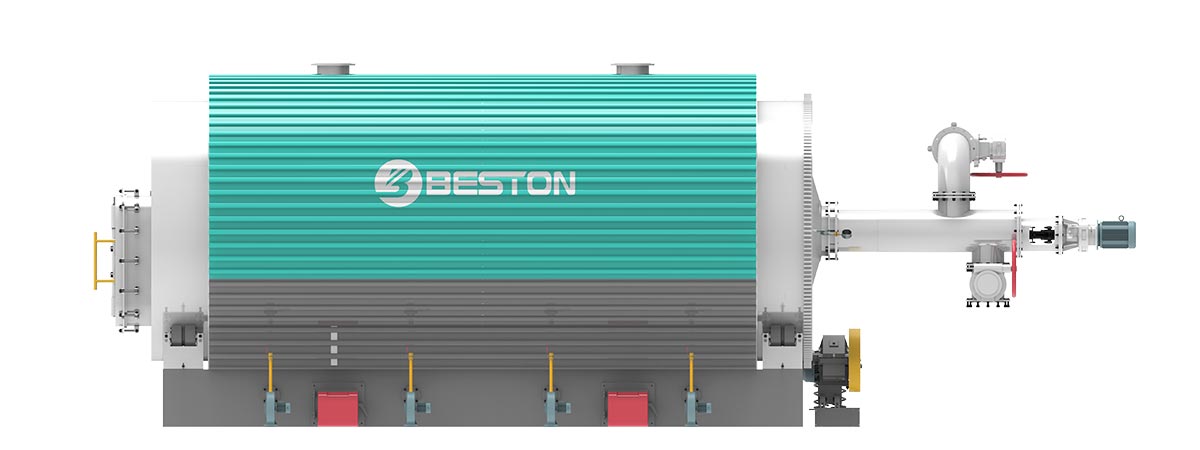

In the symphony of pyrolysis, the batch pyrolysis plant takes center stage, conducting a meticulous and controlled performance. Picture a tailored approach to waste conversion, where a finite amount of feedstock is carefully loaded into the reactor. This discrete quantity allows for a thorough and precise pyrolysis process, ensuring optimal temperature distribution and residence time.

The beauty of the batch pyrolysis plant lies in its adaptability to diverse feedstocks, accommodating variations in composition and moisture content. This flexibility renders it a versatile solution for processing small to medium-scale batches of waste, making it an ideal choice for niche applications or localized waste management initiatives.

While the batch pyrolysis plant operates with a deliberate cadence, its intermittent nature may pose challenges for those seeking continuous production. However, its ability to fine-tune the pyrolysis conditions makes it an invaluable asset for specialized industries and research endeavors demanding precision.

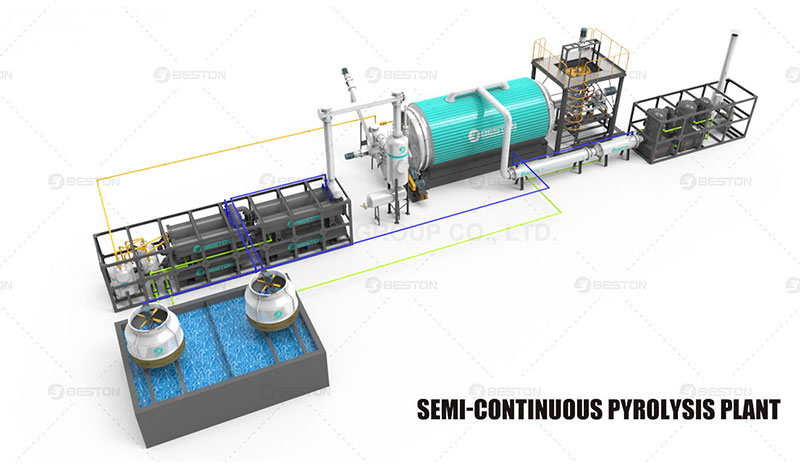

Semi-Continuous Pyrolysis Plant: Bridging the Divide

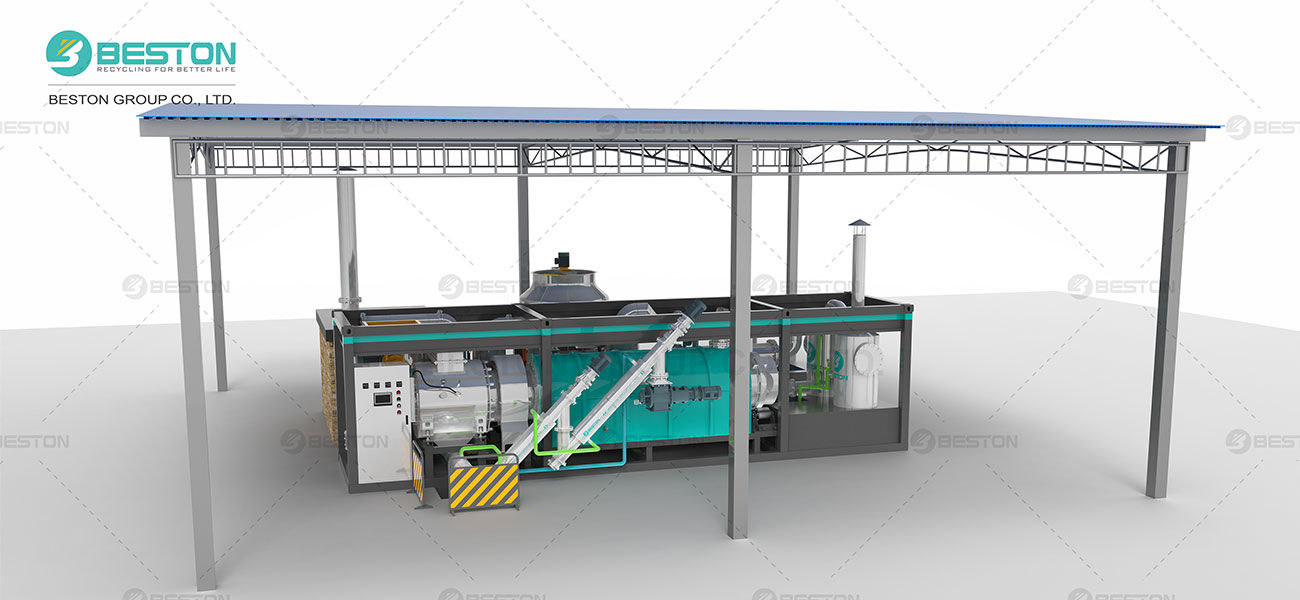

Stepping into the continuum of pyrolysis technology, the semi-continuous pyrolysis plant strikes a harmonious balance between precision and efficiency. Imagine a system that retains the meticulous approach of its batch counterpart while embracing a more streamlined and continuous operation.

The hallmark of the semi-continuous pyrolysis plant is its ability to process successive batches with minimal downtime. This is achieved by maintaining a constant flow of feedstock into the reactor, enabling a smoother transition between batches. This innovation addresses the intermittent nature of the batch system, catering to industries requiring a more consistent output without sacrificing the detailed control characteristic of batch processing.

Intriguingly, the semi-continuous pyrolysis plant integrates the advantages of both batch and continuous systems. It marries precision with productivity, offering a middle ground that suits a spectrum of waste processing needs. This makes it an appealing choice for businesses seeking a flexible solution that can adapt to fluctuating waste volumes without compromising on efficiency.

Continuous Pyrolysis Plant: Pinnacle of Efficiency

In the grand tapestry of pyrolysis technology, the continuous pyrolysis plant emerges as the zenith of efficiency and productivity. Visualize an unbroken procession of waste-to-energy conversion, where feedstock seamlessly enters the reactor, and the resultant products flow in a perpetual stream.

The defining feature of the continuous pyrolysis plant is its non-stop operation, eliminating the pauses inherent in batch and semi-continuous systems. This perpetual motion not only maximizes throughput but also minimizes energy fluctuations, contributing to a more stable and efficient process.

The continuous nature of this system is particularly advantageous for large-scale industrial applications where a steady output is paramount. The seamless integration of feedstock, pyrolysis, and product collection sets the stage for a highly automated and resource-efficient operation.