With growing environmental awareness and demand for sustainable energy solutions, converting waste wood into high-value products has become a practical and profitable approach. Turning discarded wood into charcoal or briquettes not only reduces waste but also provides a renewable energy source that can be utilized in households and industries alike. By understanding the processes and technologies involved, businesses and communities can enhance the value of otherwise underutilized materials.

Understanding the Conversion Process

The transformation of waste wood into charcoal involves a process of controlled heating in the absence of oxygen, which removes water and volatile compounds while leaving behind carbon-rich material. This process not only generates charcoal but also produces byproducts like wood vinegar and biochar, which can be used in agriculture and other industries. The efficiency of the process largely depends on the type of wood, moisture content, and processing technology.

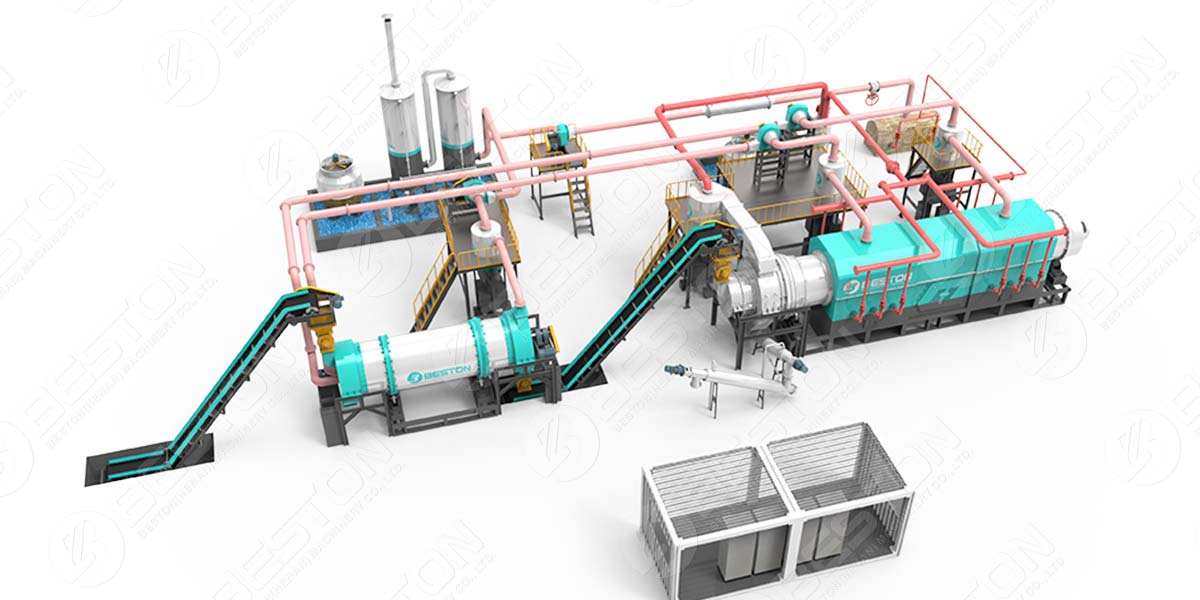

Using Advanced Equipment for Efficiency

Modern technology plays a vital role in producing high-quality charcoal. Investing in a wood charcoal machine allows for controlled pyrolysis, ensuring consistent quality and higher conversion rates. For communities or small-scale operations, these machines offer a way to turn low-value waste into a product that can compete in the market. Continuous operation and automation reduce labor costs while improving output.

Choosing the Right Wood for High-Quality Charcoal

Not all wood types yield the same quality or quantity of charcoal. Hardwoods such as oak, maple, and hickory tend to produce denser, longer-burning charcoal compared to softwoods. Moisture content is another critical factor; wood should be adequately dried to ensure higher carbon content and reduce smoke during processing. Proper selection of raw materials helps in maximizing both yield and the final product’s market value.

Producing Charcoal Briquettes for Added Value

Charcoal briquettes are a popular form of processed charcoal that can fetch higher prices than raw chunks. By compressing charcoal powder with binders, briquettes are uniform in size and burn efficiently, making them ideal for household or industrial use. A charcoal briquette machine simplifies this process, allowing operators to produce consistent, high-quality briquettes that meet market standards.

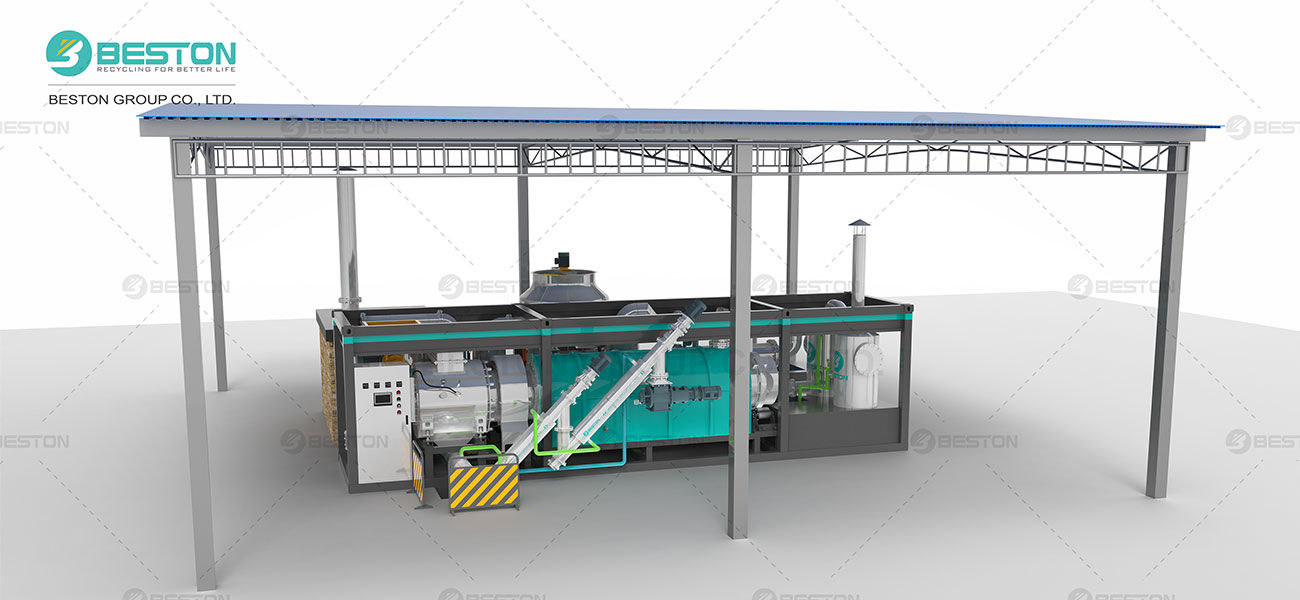

The Role of Biochar in Value Addition

Beyond fuel applications, biochar derived from waste wood serves as an agricultural amendment that improves soil quality, retains moisture, and reduces greenhouse gas emissions. Utilizing a biochar production machine enables producers to tap into the growing demand for eco-friendly products. By diversifying output into both energy and agricultural markets, operators can enhance overall profitability and sustainability.

Environmental and Economic Benefits

Converting waste wood into charcoal not only provides economic benefits but also contributes to environmental sustainability. It reduces deforestation pressures, diverts waste from landfills, and generates renewable energy. Moreover, products like biochar contribute to carbon sequestration and soil enhancement. By adopting efficient equipment and technology, operators can achieve a balance between profitability and environmental responsibility.

Market Opportunities and Profit Potential

The market for charcoal and briquettes continues to grow, driven by demand for cleaner cooking fuels, industrial applications, and sustainable agricultural products. High-quality charcoal and briquettes command higher prices, and biochar adds another revenue stream. By investing in reliable equipment and following best practices, businesses can turn waste wood into a profitable and eco-friendly resource. Welcome to consult Beston Group for biochar production solution.

In conclusion, transforming waste wood into charcoal and related products offers significant opportunities for adding value and promoting sustainability. With the right selection of raw materials, advanced machinery, and optimized processes, both small-scale and commercial operators can generate high-quality products that meet market demand while contributing to environmental protection.