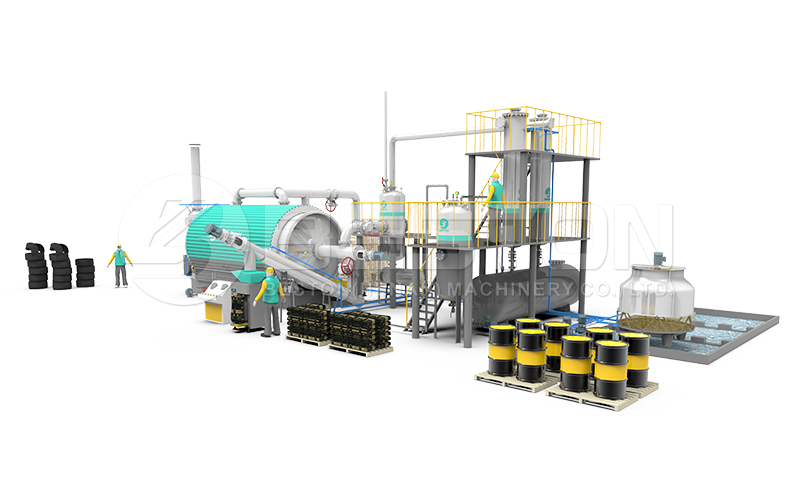

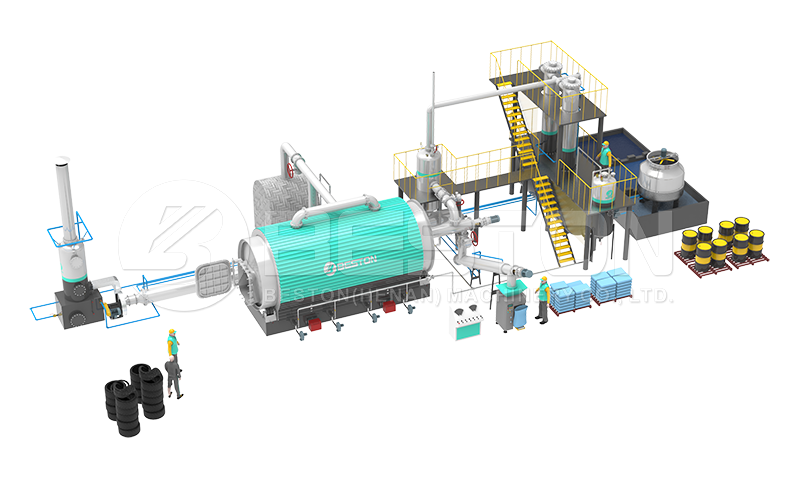

Choosing a suitable pyrolysis plant manufacturers is difficult because there are so many manufacturers to choose from. Some of these manufacturers are trustworthy and sell quality waste pyrolysis plant and they have full customer service. Moreover, a manufacturer that has a good reputation, also offers a warranty, has several years of experience, has excellent customer service, and has affordable prices, such as Beston Machinery in China.

Here is how to choose the best pyrolysis plant manufacturer.

1 Years of Experience

The best pyrolysis plant manufacturers have been in this industry for several years. They have worked with a lot of people and businesses. So, when you find a manufacturer, find out how long the manufacturer has been in this industry.

Avoid new manufacturers because they do not have enough experience. In fact, most of the new manufacturers do not have a proven track record, so it is hard to know the quality of their pyrolysis plants. Moreover, they also have various options for you, such as tyre pyrolysis plant. If you want to reduce your tyre recycling machine cost, you need an experienced manufacturer.

2. The Reputation of the Manufacturer

You may find manufacturers that have several years of experience, but they have a negative reputation. They have a negative reputation because they make poor quality pyrolysis plants. In fact, these manufacturers do not have loyal customers. And they have poor customer service.

Reputable pyrolysis plant manufacturers are the best. They have a lot of loyal customers. And their pyrolysis plants are the best in the market. It is easy to select a reputable manufacturer because reputable manufacturers have good reviews and customer testimonials.

3. License

There are manufacturers that are operating illegally. They do not have a license. If you meet some of these manufacturers, they will tell you a license is not necessary. Avoid these manufacturers because they may not be qualified to make pyrolysis plants.

The best pyrolysis plant manufacturers have a license, which means they have undergone the licensing process. Licensed manufacturers hire employees who are highly qualified for this job. So, you will always have peace of mind using companies that have a proper license.

4. Location

Last, but not least, it is easy to find international manufacturers online. So, most people prefer buying pyrolysis plants from international manufacturers. They do not check out local manufacturers. In fact, some of these people prefer spending a lot of money on an international manufacturer.

There are great local manufacturers that have been making pyrolysis plants for several years and they have a good reputation. And most of these local manufacturers have cheaper prices. So, you will save a lot of money by buying a pyrolysis plant from a local manufacturer.

You now know how to choose the best pyrolysis plant manufacturers. Look for manufacturers that make high-quality pyrolysis plants. Do proper research, especially if you are looking for these waste recycling plants manufacturers for the first time. If you find a manufacturer that does not have a license, avoid that manufacturer.

In conclusion, choose a pyrolysis plant manufacturer that has several years of experience and has a good reputation. Ask for a copy of their license. And choose a manufacturer in China because they have cheaper prices.