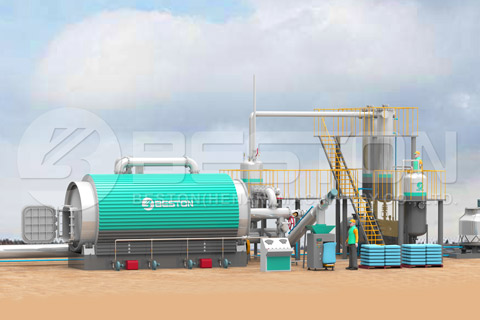

A waste tyre pyrolysis plant lets you get a lot of work done quickly. If you have access to old tires and have no way of disposing of them, you should invest in a waste tire pyrolysis plant to convert the old tires to fuel oil and carbon black. The tire pyrolysis plant is also known as a tire to oil plant because it converts old tires into fuel oil. You can process the fuel oil and convert it into gasoline and by selling the gasoline to industrial businesses in the region. That’s why a tire pyrolysis plant is the best way to make a handsome profit if you have old tires. This article provides information on why you need to invest in a waste tire pyrolysis plant for business.

Old tire disposal is a big issue across the globe with negative consequences to the environment. The best way to dispose of old tires in an eco-friendly manner is to recycle them into carbon black and fuel oil. That’s why you need a tire recycling machine, namely tyre pyrolysis machine. A pyrolysis plant will protect the environment while helping you to make extra cash by selling fuel oil, carbon black, and steel wire. If you want to know more about the pyrolysis plant profits, you can check the link here: https://bestonasia.com/pyrolysis-plant/is-pyrolysis-plant-profitable/.

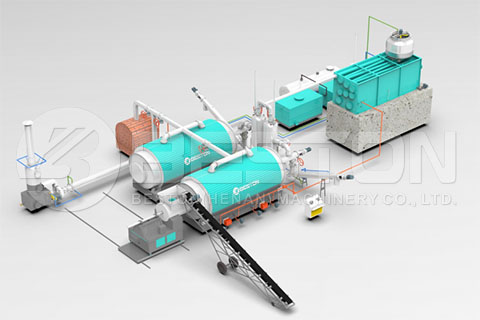

The tires should be of the right size and dry to accommodate in a pyrolysis plant. The old tires need to be shredded into small pieces and dry so that they can be transferred into the pyrolysis plant. You may also have to invest in a tire shredding machine and drying machine which isn’t that expensive. When the tires are shredded to the right size, you will get perfect gasoline as an end product from the pyrolysis plant. The plant will make fuel oil quickly and perfectly when you input the right sized tires into it.

Fuel oil is used to operate industrial machines, and there is a good demand for this product. On the other hand, you can further process fuel oil and convert it into gasoline which is quite expensive in the market. You will easily make a good profit when you invest in a pyrolysis plant for sale. With hundreds of tire pyrolysis plants on the market today, you may find it difficult to choose between a perfect and cheap machine. That’s why you need to buy a machine from reliable pyrolysis plant manufacturers in the market. Don’t forget to do your homework about the manufacturer or supplier before investing your hard-earned money in such a machine.

The internet is a good place to find reliable tire pyrolysis plant manufacturers and suppliers out there. A search on Google or any other search engine will give you access to dozens of tire pyrolysis plant manufacturers out there. Many people make the mistake of buying from the first manufacturer on Google SERPs without performing a background search on these manufacturers. Make sure you research the manufacturer’s experience, reputation, credentials, quality of the machine, price of the plant, and customer feedback before investing in the tyre recycling business.