Pyrolysis plants are available at a range of prices, depending on the reactor structure, model, and additional equipment. The cheapest models usually start at $29,000, while the most expensive can cost up to $75,000. Additional equipment can also be added to the plant to increase its efficiency and throughput. This equipment includes a feedstock pre-treatment system, a product cooling system, and an automated feeding and discharging system. If you are planning to buy a pyrolysis plant(Venta de Planta de Pirólisis) for the first time, it’s wise to compare the prices of different models. Here are a few factors to consider while comparing the prices:

1. Daily capacity

The size of the plant will dictate how much waste can be processed on a daily basis. Some pyrolysis plants are small, processing only a few tons of waste per day. Others are large-scale operations that can handle hundreds of tons of waste each day. The daily capacity of a pyrolysis plant is an important consideration when choosing a plant, as it will dictate how much waste can be processed over time.

2. Working method

Pyrolysis plants usually come in two different types: batch and continuous. Batch pyrolysis plants are the most common type, and they are able to process a range of different materials. On the other hand, continuous pyrolysis plants (planta de pirólisis de llantas)are designed specifically for processing one type of material. Both batch and continuous plants work by heating the material in an oxygen-free environment. This causes the material to break down into smaller molecules, which are then collected as liquids, gases, or solids.

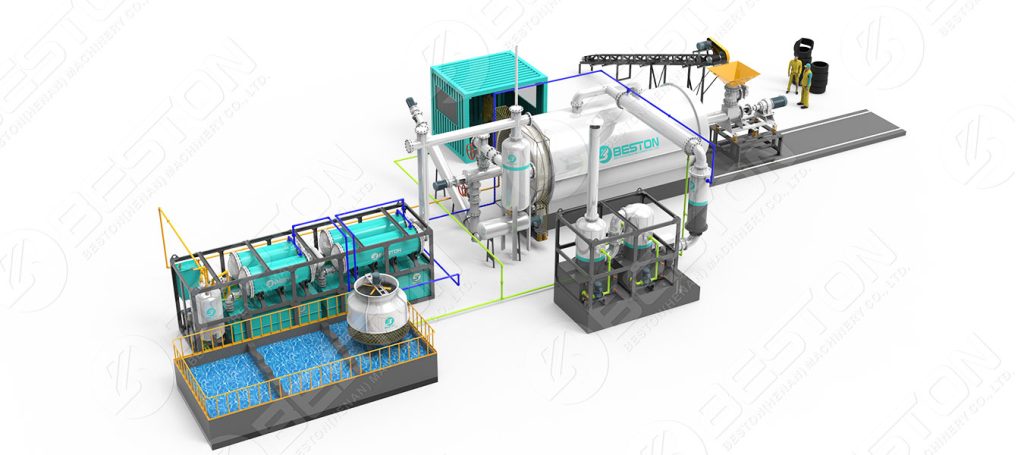

The reactor is a key component of a pyrolysis plant(https://www.bestoneco.com/trituradoras-de-llantas/). It determines the size and therefore the capacity of the plant. The size of the reactor also influences the operating costs, since a larger reactor requires more heat to operate. Some of the most common sizes for commercial pyrolysis plants are 3, 6, 9, and 12 metric tons.

4. Power source

Pyrolysis plants can be powered by a variety of different sources, including wood, coal, oil, natural gas, and electricity.

● Wood is a common fuel for pyrolysis plants, as it is inexpensive and readily available. However, wood is also a very dirty fuel, and burning it can release a large amount of pollution into the atmosphere.

● Coal, like wood, is relatively cheap and easy to obtain. However, coal is even dirtier than wood, and its use can have a major impact on air quality.

● Oil is another option for powering pyrolysis plants. Although it is more expensive than wood or coal, it does not release as much pollution into the air.

● Natural gas is more expensive than oil, but it offers the advantage of being much cleaner than any other fuel source.

They help to reduce the amount of waste people produce and also turns some of that waste into renewable energy. You can make the most of that renewable energy to operate the pyrolysis plant(Bestongroup) or even use it as fuel for cars and reduce the dependency on natural resources.