A solid egg box machine is out there, it’s just a matter of looking into what is on the market. You want to find something that is top of the line and not too expensive. That way, you spend what is fair and you come out of this a happy buyer. Get the egg box machine from reputable manufacturer.

Learn how to use a machine that makes egg boxes before you fire one up for the first time. If you don’t know what you’re doing, you can end up with a problem on your hands. For instance, if you load it up wrong, then it can malfunction and need to be repaired which can cost a lot and it can lead to your project not getting done on time. You can usually find a manual of some kind that teaches you how to work something like this so look into that to find out more. Get this line on this page https://bestonmachinery.com/egg-tray-manufacturing-machine/.

So many options are out there that are going to be a good buy, but you’re going to learn when you do your research that there are some that are not worth the money. To find out which is which, you’re going to need to look up reviews on each machine that you are thinking of buying. Don’t spend money on anything that is known for being a bad deal because it has a lot of issues. When most reviews tell you something is going to be worth it, that’ when it’s wise to spend your money on something.

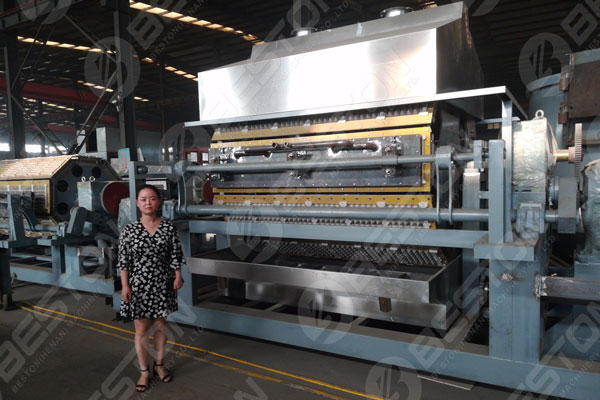

A machine can be found for cheap if you get it in used condition. But, if you’re going to go this route, it’s important that you find one that is still in awesome shape. In other words, you’re going to want to test out something before you spend money on it if it’s in used shape so you can get a feel for what it is like and so you can avoid anything that isn’t in good condition. There are some sellers that try to get rid of things that don’t work all that well so you have to be careful. See a large-scale model https://bestonmachinery.com/egg-tray-making-machine/5000-5500/.

Some of the machines out there are going to be different than others as time goes on. This is why you need to learn everything you can about the newest machine you can afford. You don’t want to go with something that is old and is known for having a lot of issues. There are usually newer models that allow for you to get a much better deal because they have features that make them easier to use in general. If you go with something that is very old then it can lead to you not being as happy with how everything works for you.

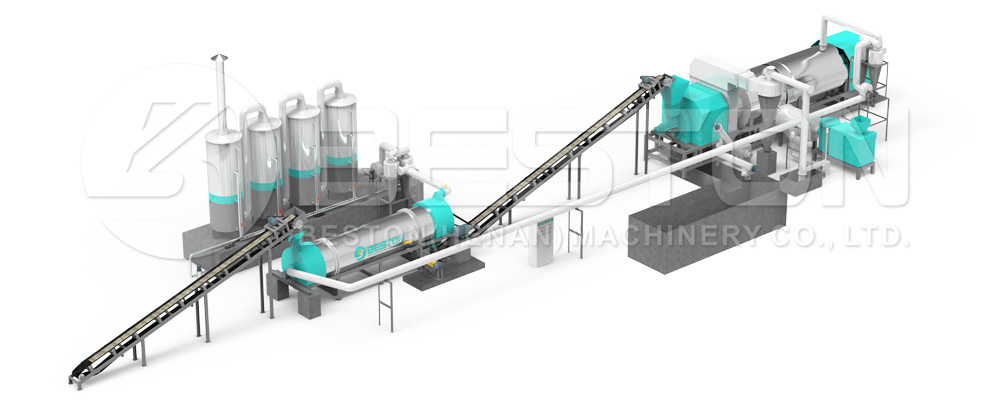

It’s important to find an egg box machine that is worth the money. If you want to do that, you’re going to need to use these tips. That way, you can get something that you know is going to be a good buy and that will work for you for projects you have in mind. Click BestonMachinery.com/ to see seven models.