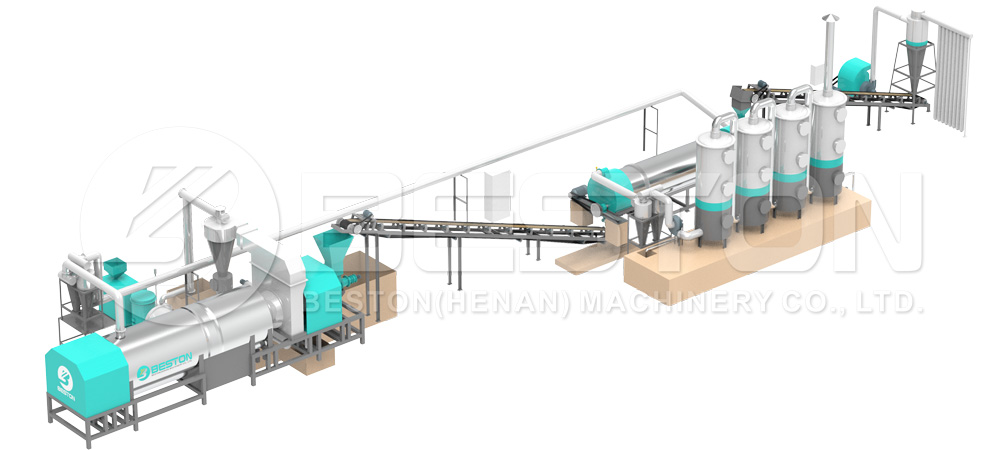

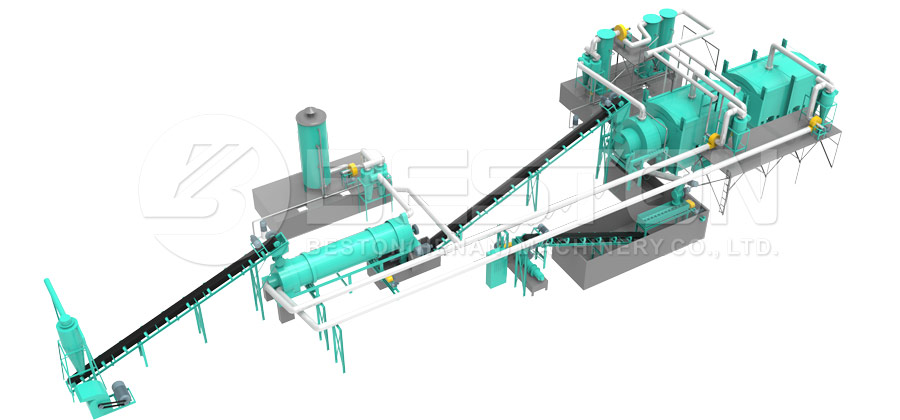

Many people who are looking to make money in the fire industry are asking the question, “how to buy a charcoal manufacturing plant?” If you are looking to make some money in the business then you will have to look into purchasing a good factory that can produce enough chemicals to fill the needs of a large company. The good news is that there are several companies out there that will provide you with a quality product at a reasonable price.

One of the best ways to find a good factory for your business is to look online. You will be able to find a large number of websites that will provide you with all the information you will need to make a decision about what type of manufacturing plant will work for you. If you find a company online, then it is important that you do your research on the website to see if they have good customer service and are trustworthy. When you are looking for a company to purchase a charcoal manufacturing plant from, you want to make sure that they have a good reputation and are reliable. Click here to know more about the palm kernel shell charcoal machine.

Another way to locate a good company that produces high quality products is to ask around in your local community. You may even have friends who are employed by different factories or businesses that manufacture chemicals. You may find that they have some good advice that can help you decide if you are a good candidate for purchasing a manufacturing plant from a specific company. Another great way to get advice on the best company for purchasing a manufacturing plant is to look through business magazines. These magazines often include information on many different businesses and industries.

Once you find a factory that you are interested in buying from, the next step is to research them. In this step, you should take the time to go through their website and to make sure that you are not getting ripped off by any company. After you have done this, you can then make an informed decision on whether or not they are a good company to purchase from. You may also want to check out their history in the business to make sure that you are getting a reputable company that will give you everything you need for your business.

Once you have done your research and found a company that can help you with a manufacturing plant, you will then need to consider how you can purchase the plant. You should consider all of these things before you purchase anything in order to ensure that you do not fall victim to someone that is trying to steal your money. Find more information on biochar machine for sale here.