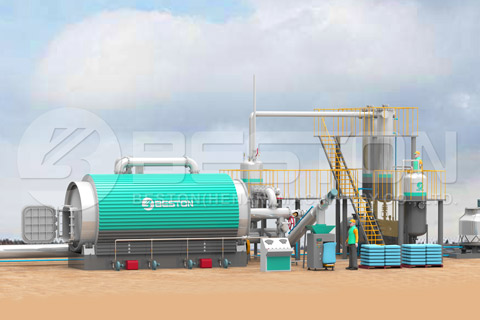

The pyrolysis plant is one of the best things you can buy for your recycling business. This plant allows you to get a lot of work done and it won’t take long to find what you are looking for when you choose this plant. The pyrolysis plant for sale is easy to use and you can get a lot of work done with it.

When you are looking for a pyrolysis plant it is very important that you choose a plant you can afford and that also has all of the features you need. This plant is going to be easy to use and it will also help you produce more oil and charcoal.

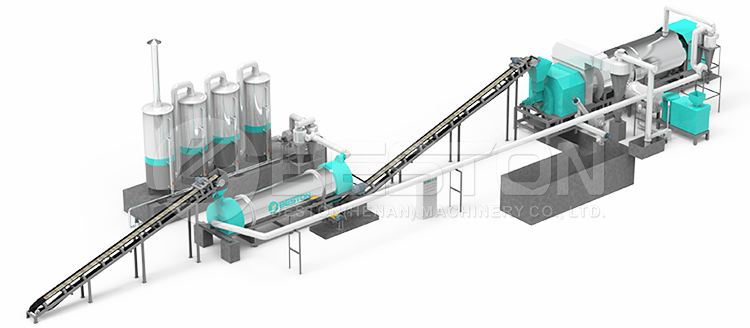

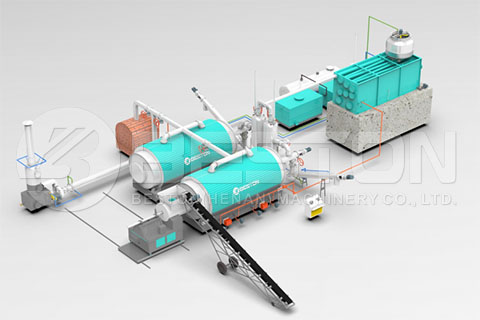

The pyrolysis plant takes biomass or waste rubber and heats it up. During the heating process the charcoal or oil is created and you can easily take care of your needs with the plant. You have a lot of choices when you are looking for the plant and you want to make sure that you take the time to find the plant that is going to be the best fit for your needs. Click here to know more: https://bestonpyrolysisplant.com/fully-continuous-pyrolysis-plant/.

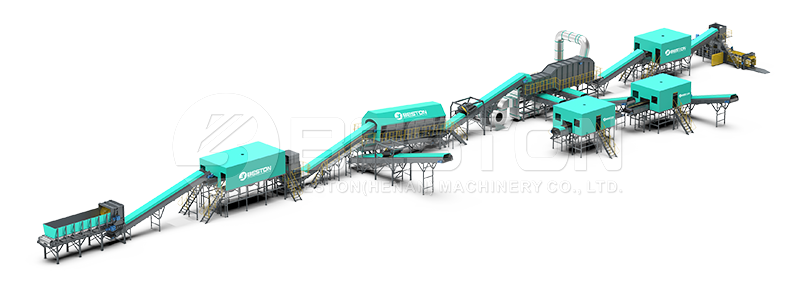

There are so many choices that you have when you are looking for the plant and you can easily find a machine that is going to be the right fit for your needs. A good plant helps you get a ton of work done and you won’t have to worry about a lot of problems when you are looking for the plant you need.

When you are ready to buy a plant the first thing you have to think about is what kind of pyrolysis plant you need. You have to decide whether you want a plant that is going to burn rubber or transform coconut shells and other biomass.

Workers are going to have an easy time using this tire to oil plant and it is going to help them get a lot of work done. They won’t feel hot or uncomfortable when they are using the plant which is very important when you want to take care of a lot of work quickly.

The plant is affordable and it helps you to take care of a lot of work fast. When you are looking for the right plant make sure that you take your time and look for the plant that is going to help you get a lot of things done. The best plant is going to be affordable and it is going to have all of the features you are looking for.

There are so many things you can do with this plant and it is a great investment in your business. This plant provides you with so many opportunities and it will help you take care of all of your needs. This plant is a great investment. Also, you can find more on this: https://www.reddit.com/user/bestongroup/.