The average daily energy requirements of the world are increasing year on year. As a result, many companies are focusing their attention on providing alternative means of energy generation. It has since been realized that there is lots of energy in city garbage, so now there are lots of machines in the marketplace that can convert waste materials like tyre, rubber, wood, paper, sand, etc., into fuel. One of the most popular machines in the marketplace at the moment is the tyre pyrolysis machine, which can convert waste tyres into pyrolysis oil. The costs of pyrolysis machine depend on many factors.

Where To Find The Great Pyrolysis Machines?

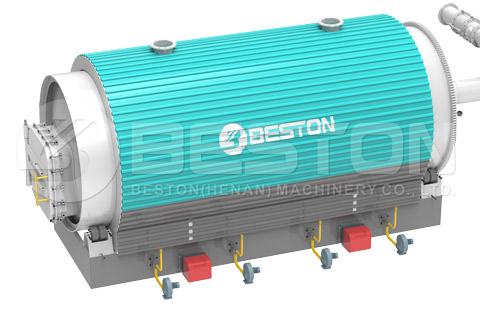

There are now pyrolysis reactor manufacturers all over the globe. What’s even better is that most suppliers of such industrial waste to energy machinery offer cheap international shipping and export to many different countries including USA, China, Indonesia, UK, Norway, South Africa, Romania, Philippines and more. For the lowest prices and highest quality reactors, you generally need to look towards pyrolysis machine manufacturers who are based in China. The main reason why pyrolysis reactors are cheaper in China is that the cost of labor and raw materials in the country are very low. Get a reasonable pyrolysis reactor cost from these manufacturer.

Evaluating Pyrolysis Machine Manufacturers

The best pyrolysis machine manufacturers are able to provide lots of detailed information about their models, including extensive specifications and results of extensive testing methods. Some of the best suppliers sell machines that have the following characteristics:

1. Use the latest advanced technology in the field of waste pyrolysis.

2. Use high-quality, durable components to create machines with long working life spans.

3. Export to customers all of the globe and don’t just focus on local niche markets.

4. Offer a vast product line that caters to small-scale and large-scale waste processing plant owners.

5. Affordable pricing structure.

6. Easy to source replacement parts.

7. Excellent after-sales packages that include machine assemble and operator training.

8. Low running costs due to high energy efficiency ratings.

9. Capable of meeting stringent environmental standards. The best pyrolysis plants produce no toxic emissions.

Add On Pyrolysis Machines

It’s important to note that once tyre waste has been processed into fuel oil via the pyrolysis process, to make more profits, waste management firms have to put the oil through further refinement processes. While pyrolysis oil can be easily sold in its raw state, it commands better prices when it is refined in a distillation machine into diesel oil or gasoline.

Conclusion

If you are planning to invest in any sort of pyrolysis machinery for your tyre waste processing recycling plant, product and supplier research is of utmost importance. Don’t be afraid to check out pyrolysis reactor model reviews from previous verified purchasers. Also, as previously mentioned, if you want to avail of the lowest prices and best quality equipment, you need to look to suppliers in Asian countries like China. On a final note, make sure you check out the estimated working life span of a machine before you hand over a cash deposit to any vendor. This is the homepage which provides several machines: www.bestonmachinery.com.