Charcoal, a solid residue obtained from the carbonization of biomass, has been utilized for centuries as a valuable fuel source and a precursor to various products. In recent years, charcoal production equipment has found innovative applications in industries such as metal smelting and chemical processing. This article explores the versatile uses of charcoal production equipment in these industries and highlights the benefits it offers.

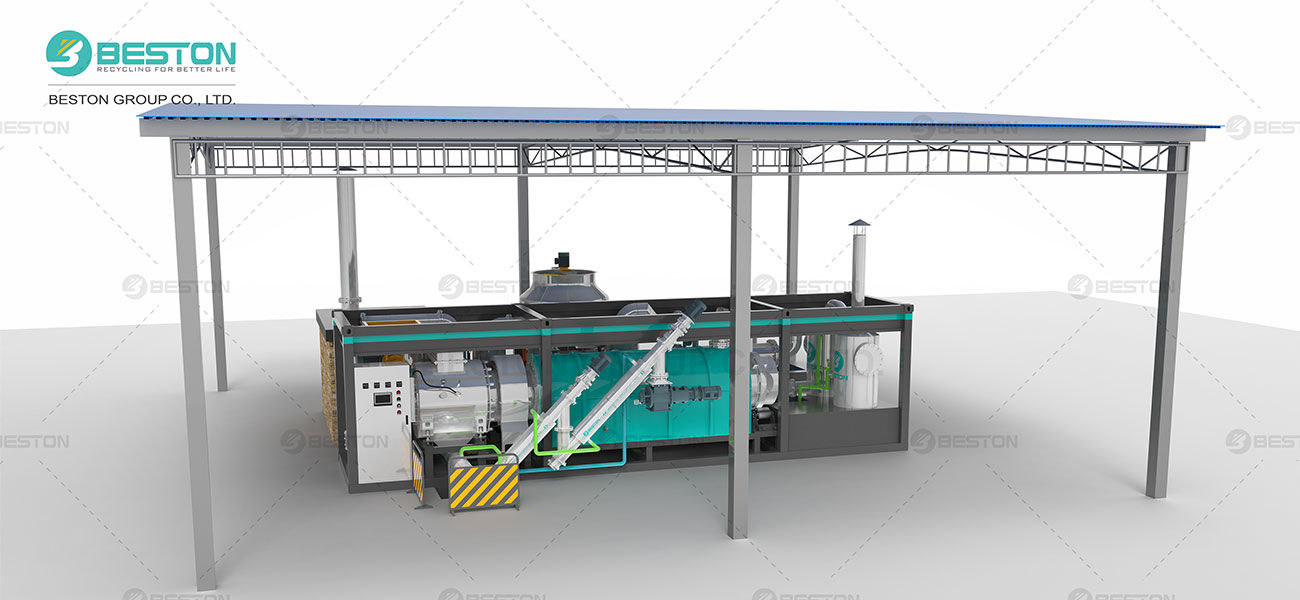

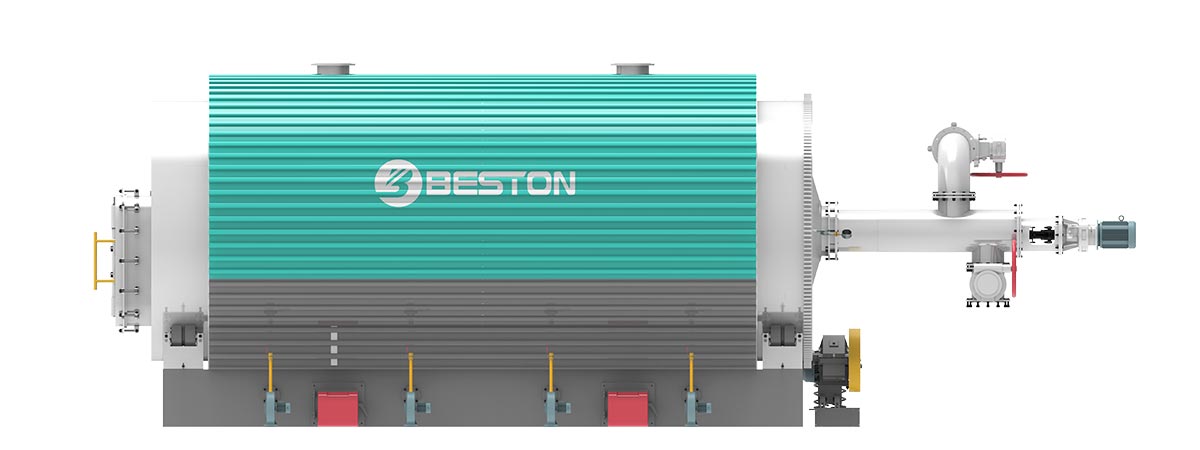

Charcoal Production Equipment Overview

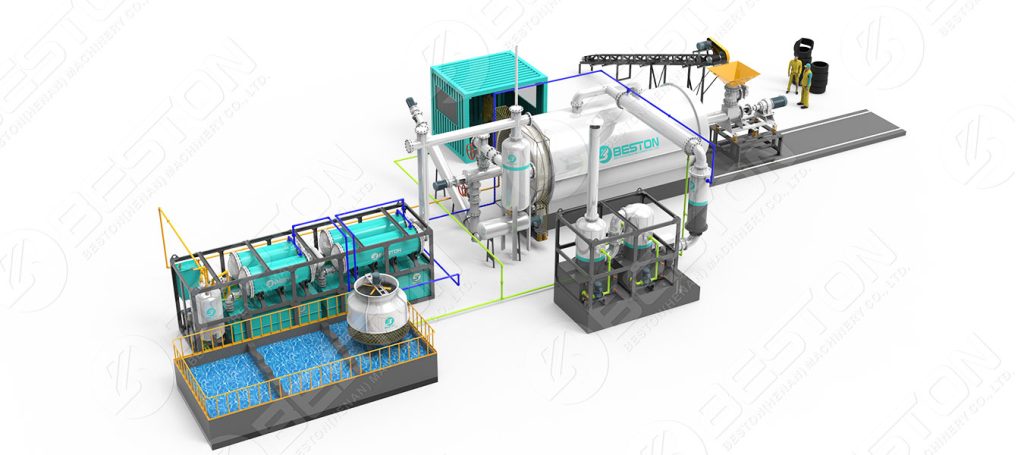

Biochar production equipment involves the carbonization of biomass through pyrolysis, a process that removes volatile components, leaving behind a high-carbon content solid material known as charcoal. This equipment includes pyrolysis kilns, retorts, and reactors that provide controlled conditions for the carbonization process.

Applications in Metal Smelting

1. Blast Furnace Fuel

Traditionally, coke, a form of processed coal, has been a vital fuel in blast furnaces used for iron and steel production. However, charcoal can serve as a suitable alternative. Charcoal’s high carbon content and low impurity levels make it an attractive option for reducing iron ores, resulting in cleaner and more efficient metal smelting processes.

2. Reduction Agent

Charcoal’s ability to release carbon monoxide when heated makes it an excellent reduction agent. In metal smelting, charcoal can be used to reduce metal oxides, converting them into metal and carbon dioxide. This process plays a crucial role in extracting metals from their ores, enhancing process efficiency and reducing energy consumption.

3. Direct Metal Production

Charcoal from charcoal machine can be utilized in direct metal production processes, such as direct reduction of iron ore and non-ferrous metal production. By using charcoal-based reduction, industries can achieve higher metal yields, lower greenhouse gas emissions, and reduced reliance on fossil fuels.

Applications in Chemical Industries

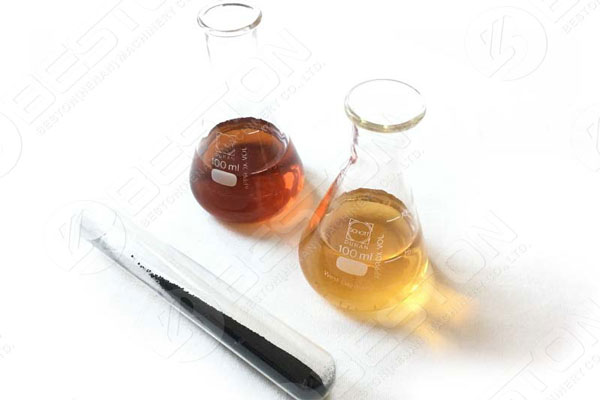

1. Activated Charcoal Production

Activated charcoal, known for its high adsorption capacity, is widely used in the chemical industry for purification, filtration, and separation processes. Charcoal production equipment can generate the base material required for activated charcoal production. The resultant activated charcoal is employed in water treatment, air purification, and pharmaceutical applications.

2. Chemical Synthesis

Charcoal’s porous structure provides a suitable medium for catalytic reactions. For example, in chemical synthesis of sawdust charcoal making machine, charcoal-supported catalysts can facilitate various reactions, including hydrogenation, dehydrogenation, and oxidation. These catalysts enhance reaction efficiency and yield while minimizing undesirable byproducts.

3. Carbon Source for Chemical Processes

Charcoal’s carbon-rich composition makes it a versatile carbon source for chemical processes. It can be utilized as a precursor material for the synthesis of carbon-based chemicals, such as carbon black, graphene, and carbon nanotubes. These materials find applications in electronics, advanced materials, and energy storage technologies.

Benefits and Considerations

Here is a list of some of the benefits of biochar production equipment, you can also click on Beston Group for more information.

1. Environmental Benefits

The use of charcoal produced from sustainable biomass sources can contribute to reduced greenhouse gas emissions and deforestation. Charcoal’s potential to replace fossil fuels in various applications aligns with efforts to mitigate climate change.

2. Resource Efficiency

Charcoal production equipment allows industries to utilize biomass waste streams, agricultural residues, and wood scraps that would otherwise be discarded. This promotes resource efficiency and reduces waste.

3. Economic Viability

Charcoal production equipment offers economic benefits by creating value-added products from low-cost feedstock. Industries can diversify their revenue streams while optimizing their production processes.